Applications

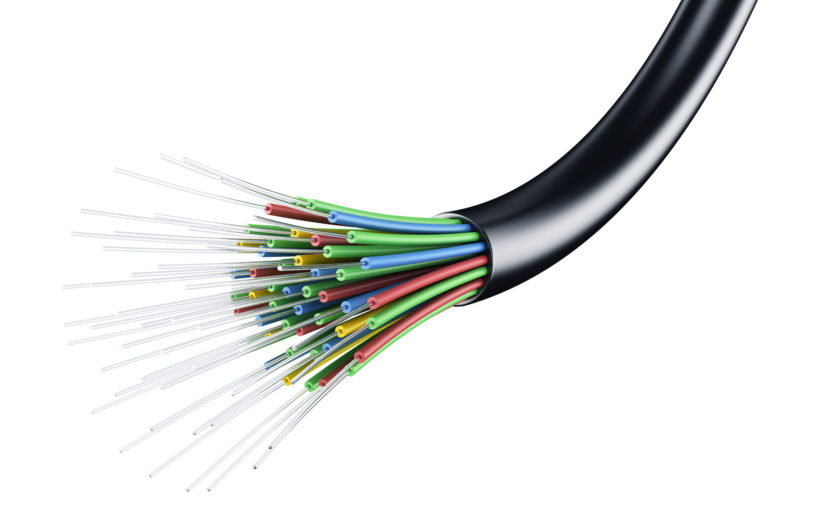

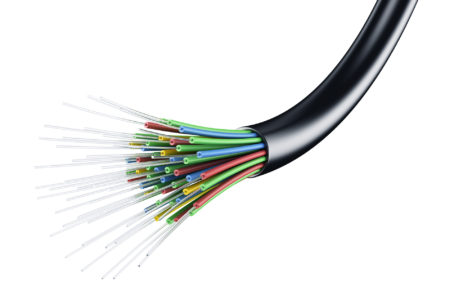

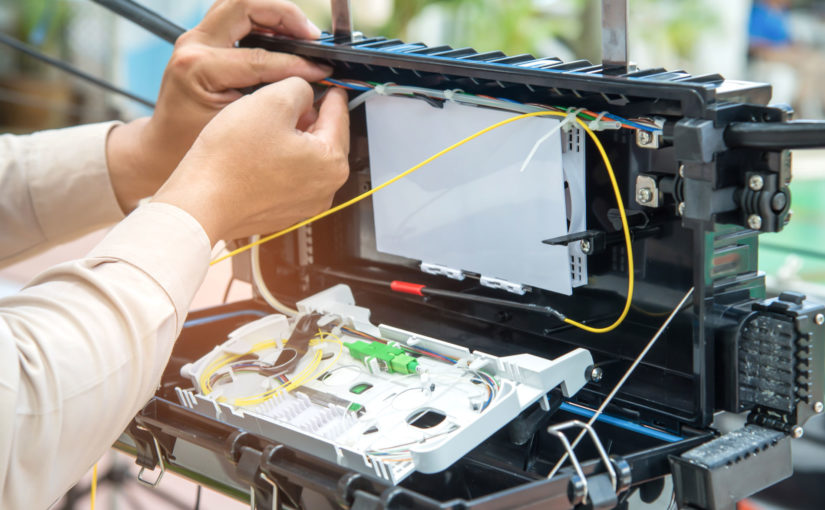

As the popularity of optical fibers continue to grow, so does their applications and practical uses. Fiber optic cables became more and more popular in a variety of industries and applications.

- Communications / Data Storage

- Mechanical or Industrial

- Networking

- Internet and telecommunications

- Automotive Industry

Fiber optics are the best choice for businesses requiring long distance cabling and high bandwidths, as it’s reliable and can support future growth.

Few more Advantages are:

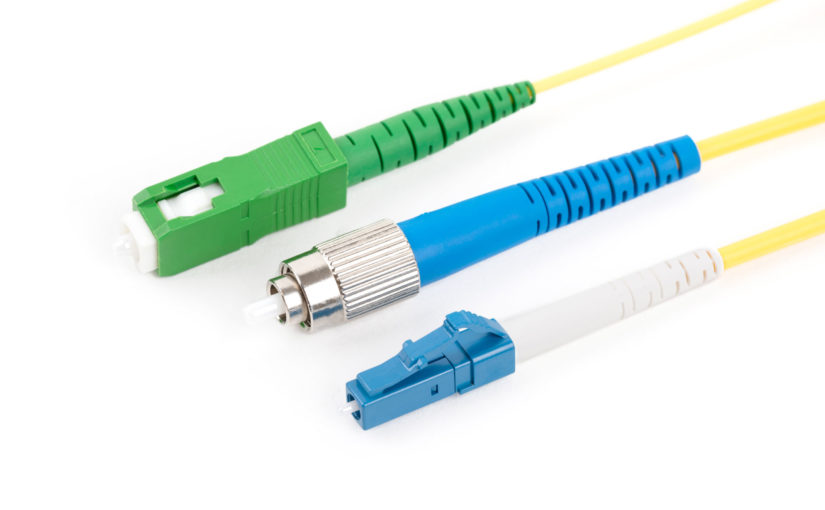

- fiber-optics are replacing copper wire as an appropriate means of communication signal transmission

- Support of higher bandwidth capacities.

- Light can travel further without needing as much of a signal boost.

- They are less susceptible to interference, such as electromagnetic interference.

- They can be submerged in water- fiber optics are used in more at-risk environments like undersea cables.

- They do not need to be maintained or replaced as frequently.